By Christy Heady, originally published in the Berkshire Edge

March 12, 2015

Pittsfield, MA – Business executives are bullish on the future of Berkshire County.

There is a new spirit of collaboration and innovation at work, aiming to catapult the Berkshires and its surrounding region into a period of economic growth, accompanied by job creation and retention.

For Stephen Boyd, president and CEO of Boyd Technologies in South Lee, Mass. — and a graduate of Monument Mountain Regional High School — the possibility a dynamic and growing future for his hometown and home state excites and intrigues him. Despite the presence within Berkshire County and its surrounding region of many strong organizations, the lack of connectivity among companies and research institutions has stymied success. The solution? The Berkshire Innovation Center.

“If you take a look at the Berkshires, you’ll find promising activity in the development of medical devices and also in related research, yet within the immediate region there are no teaching or research hospitals nor academic support for technology,” he said. “The mission of the Berkshire Innovation Center (BIC) is to address this deficit.”

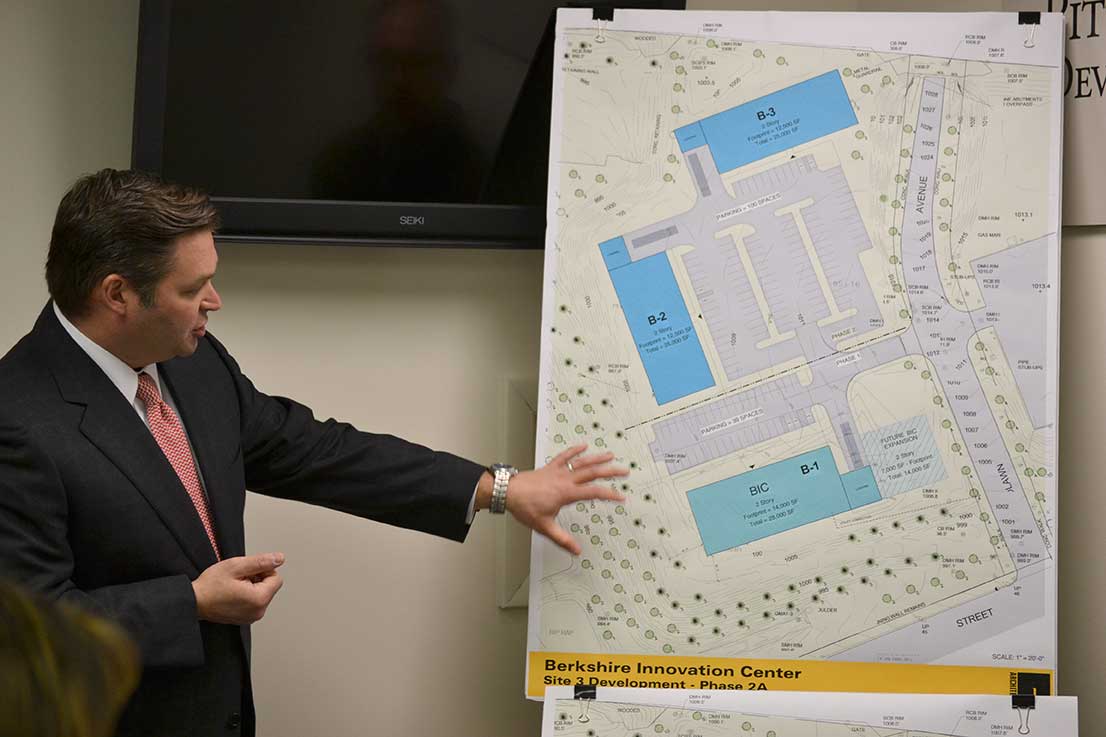

The Berkshire Innovation Center (BIC) is a 20,000-square-foot structure that will be built in William Stanley Business Park of the Berkshires, located in Pittsfield; its mission is to advance the manufacturing strengths of the region. The project is made possible by a state grant of $9.7 million from the Mass Life Science Center plus two start-up grants of $250,000 each from the Pittsfield’s economic development fund and the Pittsfield Economic Development Authority.

The impetus for the BIC came from a feasibility study conducted by Rod Jané, president of New England Expansion Strategies in Westborough, Mass. He obtained input from key influencers within the region, including private sector companies, universities, colleges, hospitals, venture capital firms, and the local government, to determine what was needed to spur economic development and the retention and creation of jobs.

What Jané initially discovered was that the existing life sciences industry – including biotech, pharmaceuticals and medical devices – was tiny. “Only a few companies and fewer than 100 employees,” Jané said. However, the study also revealed an important cluster of life sciences supply chain companies: 30 companies with more than 4,000 employees either supplying or capable of supplying the medical device industry. The clear opportunity to build on this existing strength, this cluster of life science supply chain manufacturers, strengthened the prospects that the BIC could make an important contribution.

With grant money from the Massachusetts Life Sciences Center, the study proceeded to evaluate how economic development money could be invested to yield the highest probability of success.

“There turned out to be broad industry support for an innovation center that could assist small- to medium-sized manufacturing companies, by allowing them access to advanced equipment, training, research partnerships and student internship programs,” Jané said. “These results from the feasibility study form the basis of the Berkshire Innovation Center.”

The site plan for the William Stanley Business Park of the Berkshires in Pittsfield, showing the location of the Berkshire Innovation Center (Site 3).

Ten companies have already signed formal membership agreements with the Berkshire Innovation Center. The members to date include Apex Resource Technologies, Boyd Technologies, Sinicon Plastics, Intertek PTL, General Dynamics, Interprint USA, Sonoco Plastics, MRA Laboratories, Berkshire Sterile Manufacturing and New Dalton Group.

Because he had already participated in helping to define the BIC’s mission and to grow its membership, Boyd recognized that it could help answer the strategic questions he had been asking himself for a while.

“In the midst of every business transaction I conduct, I wonder, what would happen if I did it differently or if I could take a step in a new direction,” said Boyd. “You try something, you test it, you try it again. That’s innovation.”

Pittsfield’s Director of Community Development Douglas C. Clark seconded Jané’s findings, stating that many people understand that a regional approach is essential to successful economic development.

“The City of Pittsfield or even Berkshire County alone are too small,” he added. “I look to the BIC’s becoming the hub of a network extending from Springfield to Albany in advanced manufacturing for the life science supply chain.”

Clark explained how the history of the area has shaped where the strategic thinking patterns lie today.

“In the days of General Electric, we had a huge employer that was able to fund its own R&D and workforce training programs,” Clark explained. “Intellectual property in slower changing times allowed the owner of that information to profit as long as he could protect that information. In contrast, our small to medium sized companies can’t self-fund the workforce training and R&D that are critical to remaining competitive.”

Also, because the pace of change is so rapid today, he said, “it is more about the flow of information than about the ‘stock’ of information. For this reason, it is increasingly important to collaborate and network with other firms and institutions.”

A UMass Donohue Institute study showed that the manufacturing sector still accounts for 10 percent of employment and 15 percent of all income and wages in Berkshire County. Jané said that the BIC is an economic development catalyst that can help small and medium-sized manufacturers innovate new products, train their work force in advanced manufacturing, and compete effectively with global competition.

The City of Pittsfield, Clark said, does not have the benefit of a large research institution. The collaboration provided through the BIC can fill that void, drawing on the resources of its institutional partners UMass Lowell, UMass Amherst, RPI and SUNY College of Nanoscale Science and Engineering.

“Public money is definitely seeding the project,” Clark offered. “But what I like is that this will be a private sector-led initiative and will benefit from the leadership and investment of time and effort of many of our leading local companies.”

For CEOs like Boyd, accessibility has proven a strong incentive for committing time, energy and money to the BIC.

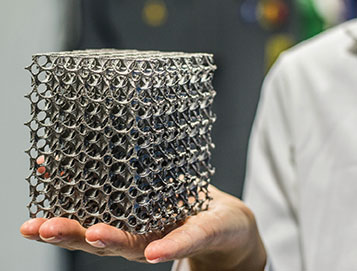

“If I wanted to buy an electron microscope that I would use to take three-dimensional pictures of nano-fiber, I would spend $300,000 on that piece, at least,” Boyd said. “There is no way my business can justify that expense while using it once a week. It’s not a revenue-generating piece of equipment. With the BIC, it’s nice not to have to buy that on my own. The BIC can buy it. Then I and other companies can join the BIC and gain access to it and other equipment.”

Companies pay a membership fee to join. Annual fees range from $5,000 to $10,000. Firms with fewer employees can take advantage of reduced rates and associate memberships which allow access to networking opportunities and attendance at events on a limited basis.

“Membership allows access to video conferencing and meeting space, BIC workshops, industry-tailored training events, and access to state-of-the-art equipment,” Clark shared. “Membership also will allow access to equipment at other facilities that have signed on as part of a regional equipment-sharing collaborative.”

“An opportunity like this $10 million grant does not come along often,” Jané said and noted how the BIC will influence the economic future of the Berkshires. “It is vitally important that everybody be in the same boat and rowing in the same direction, to make sure that the Berkshire Innovation Center is successful and sustainable and makes a difference in the future of the Berkshires and its residents.”

Since innovation happens in little steps, as Boyd said, one of the first steps toward growing the awareness of the BIC was a speaking event held at the end of January.

On January 29, 2015, at the Berkshire Community College, 40 attendees participated – including representatives of eight BIC member companies – in the BIC event, despite the heavy snowstorm the day before. The event was co-hosted by MassMEDIC. Bruce Stanley, former Becton Dickinson supply chain executive, was the guest speaker. The main topic of the evening’s discussion was the MedTech program, which will connect BIC member companies to major medical device original equipment manufacturers (OEMs).

As the BIC moves forward, Clark added, he will be focusing on building a capacity for resilience into the economy of both the city and the region.

“In the face of technological change and global competition, I am interested in seeing how we can be resilient,” he said. “The BIC will allow us to innovate, develop our workforce, and stay competitive as we face an uncertain and challenging future.”